Metal FDM again?

Given the trouble we have been having with the fine mechanical parts of the friction extrusion approach, I have opted to test a hypothesis I have had for some time, that printing metals via an FDM like process should be possible if sufficient thermal control at a high enough operating temperature with a sufficiently well positioned heater/sensor combination of sufficient sensitivity can be built.

What is "sufficient" in this case, is a somewhat complex question which depends on the desired rheological properties of the material to be printed, and the environment in which it is to be deposited. In typical FDM the viscosity of of PLA in the melt when at zero shear is typically between 10^3 and 10^4 pascal seconds. Under typical extrusion rates, shear thinning (thixotropy) reduces this value to something like ~250-500 pascal seconds (Pa*s).

From what I can tell, there are a few common objections to semisolid metal direct write, and molten metal direct write.

also see Chris Vallone's project on Hackaday.

and Michael Perrone's project on semisolid metal printing.

Listed below as I have heard them:

- Metals have melting points that are too high to be printable

- Because the melting point is high, the metal will be more prone to warping or otherwise deforming during deposition, despite the lower thermal expansion of most metals compared to polymers.

- Oxidation will prevent good layer adhesion, bed adhesion and generally impact part quality unless an inert atmosphere is used.

- the sudden eutectic phase transition of many metals will inhibit controllable rheology and thus make extrusion difficult or impossible.

- printing in the melt will yield undesirable microstructure in the printed part as it will be "necessarily" cast due to going through a liquid solid phase transition.

- no hot end/nozzle material can be worked that will tolerate molten or semi molten metals for long periods.

- the power demand of printing metals is enormous due to their high thermal conductivity and high melting points. no practical desktop machine can supply this power safely.

I intend to address these points one by one in the following paragraphs, and demonstrate a few methods I have attempted to construct a hotend which can overcome these objections and the very real material limitations which have challenged previous attempts at direct metal writing on the desktop.

Metal melting points to high?

First, on the melting points of metals from engineering toolbox:

| |

| Table 1. List of metals and alloys by melting point/range, from engineering toolbbox. |

The vast majority of metals whose costs are acceptable to a potential desktop direct metal write user have melting points below 1500 degrees C. There are more exotic materials which would be useful to print at higher temperatures, but not likely at a cost basis which makes sense for someone looking to manufacture simple mechanical or electronic parts with desirable mechanical/electrical properties beyond what plastics can achieve.

This, to me,sets a clear target operating temperature range for our hotend to operate across, ~20-1500 degrees C. If we look further down the chart in figure 1, we see there are a variety of metallic materials which can tolerate this temperature range and which are not impossibly expensive or rare. If we also supplement this chart with a table of maximum long term use temperature in air for ceramics and several ionic/covalent solids, we see that many materials that would be non wetting to molten metals are available, even among relatively common alumina-silicate based refractories used in foundry work for centuries.

| |

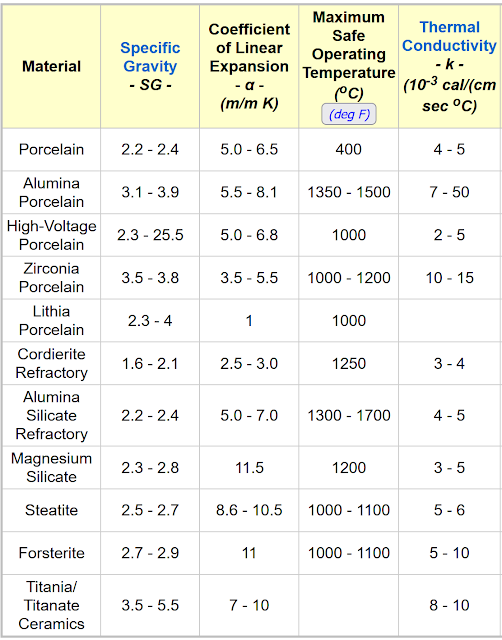

| Table 2. A snip from a table on engineering toolbox of various common refractory ceramics and their maximum safe use temperature in air. |

most ceramics perform better in inert atmospheres, but in general, the materials listed in the following table by Morgan Technical Ceramics also have exceptionally high air use temperatures.

|

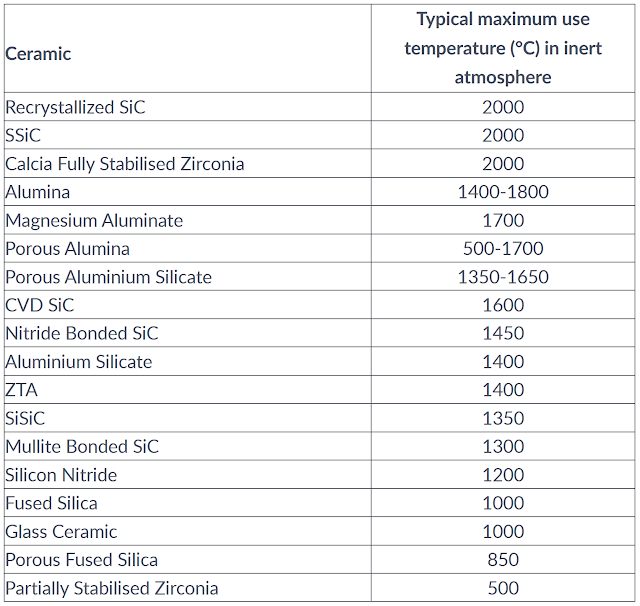

| Table 3. Inert atmosphere use temperatures of advanced technical ceramics by morgan advanced ceramics. |

Clearly, there is no great shortage of materials which could be used to construct a hotend capable, at least, of printing materials with a melting range up to 1500 C. We will discuss the manufacturing design challenges later, but for now, ab initio, no fundamental roadblock exists to building a hotend working at such temperatures.

But what about thermal expansion and print warpage?

Metals have high melting points, and high young's moduli, compared to polymers generally. This means that the metals generate large forces, comparatively, upon constrained thermal expansion and contraction. Such as, in the case of printing a new layer on top of a stack of other previous layers.

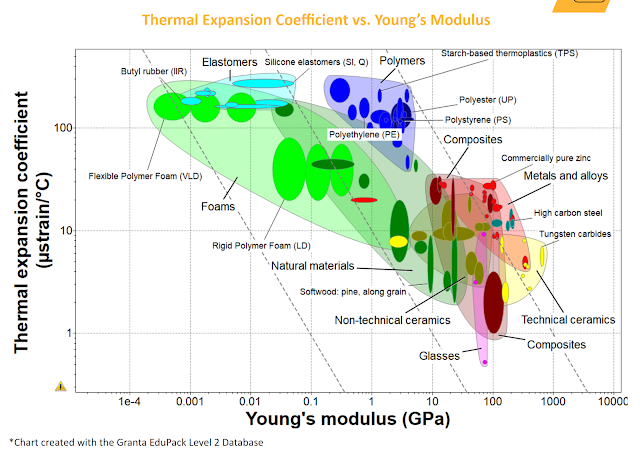

Fortunately, the thermal expansion of most metals, is also quite low compared to most polymers. as can be seen in figure 1 from ansys.

|

| Figure 1. Ansys' ashby chart of materials along axis of young's modulus (stiffness metric) and thermal expansion coefficient. |

What this means, is that metals, having higher melting points, have proportionately lower thermal expansion coefficients generally, and much greater stiffness than most polymers. For a quick example, 510 phosphor bronze, has a melting range (between solidus and liquidus) of ~954-1049 degrees C. Let us take the high end of the range to be representative of the maximal expansion to expect. The average thermal expansion of bronze between 20 and 900 C is ~18 ppm/C. For comparison, lets consider ABS, whose thermal expansion is ~120 ppm/C, and whose melting range is 190-270 degrees C. let us take the upper end of the temperature range for ABS as well.

in each case:

- Bronze :

- Tm = ~1049 degrees C

- TCE = ~18 ppm/C

- Total unconstrained expansion at melt for a part of unit dimension = 1049 * 18 = 18882 ppm

- ABS:

- Tm = ~270 degrees C

- TCE = ~120 ppm/C

- Total unconstrained expansion at melt for a part of unit dimension = 270*120 = 32400 ppm

Clearly the total thermal expansion in bronze is nearly half that of ABS for an object of equal unit dimension, despite the much higher melting point. This same trend holds generally for most metals and most polymers. the thermal expansion of polymers far exceeds that of metals generally. The problem arises when we discuss relative stiffness, and thus, the force the expansion each material generates when constrained for a given amount of expansion.

Essentially thermal expansion acts to increase the volume of an object as temperature rises. It arises from the fact that atoms in a material increase the amplitude and frequency of their vibratory motion in the material with temperature. Some materials have bonds between their atoms which are relatively stronger, others relatively weaker. The strength of these bonds arises from many factors, including the number of electrons of what orbital shell in each atom are participating in the bond, any resonant conditions which may exist, and much more that falls quickly down the rabbit hole of quantum mechanics. Suffice to say, that the bonds holding atoms together have a certain "springiness" that collectively influence the mechanical stiffness of the material. If the bonds are weaker, the material tends to be softer, and easier to bend, and change its shape, if the bonds are stronger, the material tends to be harder and more difficult to bend, or change its shape.

Thermal expansion acts to change the shape of a material when the material is constrained in some way. like a bar being heated between two immovable walls. As the bar heats up, the structure will expand, but will be constrained by the walls, this produces a stress from the constraint of the thermal expansion, termed "Thermal Stress". There is some great further reading on this available from the engineering tool box. In our case, the constraint comes from the previously deposited layers, or the build surface we are printing on. This thermal stress can be used to calaculate an associated force of thermal expansion which can be measured against the yield strength of the constraint and the material of the object doing the expanding.

The basic engineering calculation and calculator on engineering toolbox will suffice to show the point,

Calculation shown here in Figure 2, lifted directly from engineering toolbox:

|

| Figure 2. how to calculate basic thermal stress and axial force from engineering toolbox. |

In figures 3 and 4 I show results from the calculator for bronze and ABS:

|

| Figure 3. Thermal expansion, stress, force calculation for Bronze 510. from engineering toolbox calculator. |

|

| Figure 4. Thermal expansion stress, force calculation for ABS. from engineering toolbox calculator. |

to make it easier to read, the bronze stress in the expanding object is ~ 16.92 GPa, and for ABS is ~ 81 MPa in both cases, the generated stress of thermal expansion greatly exceeds the yield stress of the material. This would indicate that its nearly impossible to adhere metals together due to such enormous forces of thermal expansion being generated whenever a metal in constraint is heated to temperatures of typical welding operations.

Nevermind....

I was going to finish out this post, and be smug, but it turns out that alloy compositions are not that tightly controlled, and in general, metals contain fluxing agents like sulphur, phosphorous, manganese, and other potent glass formers that attack passivating silicon oxynitride layers and foiled our best laid plans for metal FDM.

Our chosen alloy for semisolid metal direct write, 510 phosphor bronze proved to be highly printable, with cooperative rheology, but too chemically aggressive at the required temperatures. Perhaps aluminum would be less aggressive, but unfortunately, most aluminum alloys have narrow semisolid windows.

Additionally, the semisolid direct write approach turns out not to suffer from warpage or thermal expansion, but from excessive heat conduction and low interpass temperature. In short, when printing subsequent layers, the previous layers cool down too much, and bonding becomes unreliable.

More importantly, the temperature gradient from the hot nozzle tip, is large enough that as the part volume increases, the remelting of the previous layer to facilitate bonding is further prevented by conduction to adjacent lines. this means we would need to inject more heat into the surface of the previous layer than our glowplug hotends can supply sustainably. Which implies an induction heating approach of sufficiently high frequency, and power density may be required. One example of a team already doing this is Vuecasson. There are also multiple examples in the literature of this type of printing being attempted with widely varying results.

in lieu of this and a series of major life changes, taking us to the university of chicago(Yay for photo emission electron microscopes, and a big thanks to our friend Dr. Kevin Boergens, and his awesome brain mapping work with his compatriot, Dr. Naryanan Kasthuri), and eventually to palo alto California.

Having discovered new information in the form of additive friction roll bonding, AFRB and found new hope in the solid state approach, we have opted to return to the technique and test AFRB for ourselves.

Next up, our journeys with AFRB as a technique, and hopefully some actual metal printing in due course!

No comments:

Post a Comment